Engineering and technical services:

Let us take immense pleasure in introducing to you the ANC Engineering and technical division, a professional team of engineers all graduated in mechanical, electrical and rail transportation engineering (RTE). Our team of experts hold the in depth engineering and mathematics education required to meet the challenges facing today’s railway industry. With cutting-edge training in railway operations we proudly present a list of our achievements so far:

1. Tracking and coordinating the progress of the engineering and technical projects with a detailed project execution plan :

· Playing a key role as liaison in loading, shipment and full delivery of 77 units of locos to Bandar Abbas sea port, Iran.

· Successfully upgrading 2 units of GT26 locos with the latest MEDHA Co Micro processor based control system.

2. Managing and execution of feasible technical and financial projects :

· Procurement of CDN10A locos from China

· Procurement of Micro processor based control systems from MEDHA Co India

· Planning railway fleet maintenance and repair center

3. Education :

· In work education: The course has been presented to 61 loco piloting students by Yazd and Isfahan province railway education center. The course started in mid-November 2010 and will be finished in late June 2015. The course includes both elective and required subjects and all the students who pass the finals will enter loco piloting internship afterwards.

· On-the-job training (OJT): It is training located at the job site or educational centers aiming at showing our workforce how to ace the job. In antiquity, the work performed by most people did not rely on abstract thinking or academic education. Experts who know the skills necessary for survival in railway operations pass their knowledge on to their colleges through direct instruction.

4. Quality Control:

This sector is in charge of all the quality checks for the spare parts and components ANC procures, their job as a Quality Checker falls under the broader career category of Inspectors, Testers and Sorters, Here is what they do care about:

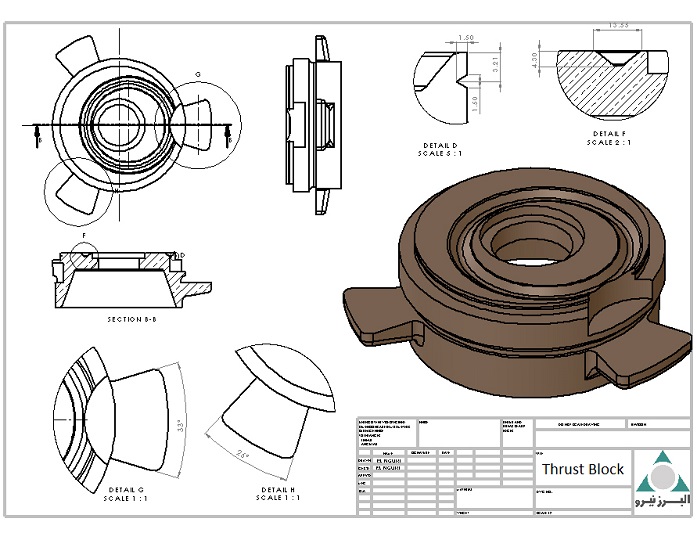

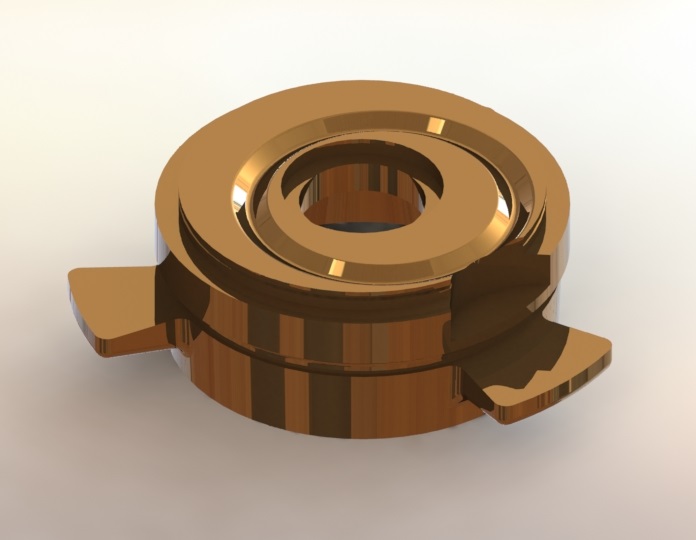

· Mechanical items including Motors, Bogies, Compressors, Main racks, Chassis and etc.

· Electrical items and electric motors including Generators , Traction motors ,Fuel- oil pump electric motors , Start motors , Radiator coolant’s cooling fans and dynamic resistors , Contactors , Relays , Electrical valves and etc .

· Inspecting products Domestic purchases and foreign procurements

· Inspecting sample products to determine if the supplier or organization can produce products ANC needs. Doing some testing on the materials to further verify quality standards in domestic purchases or foreign procurement using part catalogs.

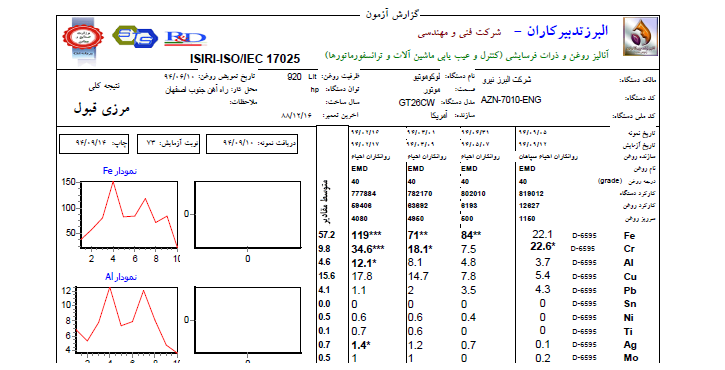

· Trouble shooting Diesel Engines using oil condition monitoring

· Nowadays oil condition monitoring (OCM) testing predictive maintenance programs are helping enterprises with different types of machines from construction machineries to military grade war machines to avoid costly machinery, engine and power-train failures. ANC OCM tests measure engine oils, lubricating oils, and other fluids for the detection of lubricant engine wear, lubricant quality degradation, and other problems. Oil conditions monitoring by ANC experts on a 15 days interval basis protect our high-value locos and reduce expensive downtime.